VEVOR XRJF-21 Double Bowl Commercial Slushy Machine

Safety Instructions

Dear user,

Hello! Thank you for using our products, for you to better read this manual and use this product, and to prevent personal injury and object damage accidents, please be sure to read carefully and comply with the following symbols in this manual.

- Behavior or action that must be prohibited

- If the operation is wrong, it may cause harm to the user

- The behavior or action that must be followed

- If the operation is wrong, it may cause damage to goods and property

Be sure to store this book in a location where users can access it at any time

Electrical Requirements

Be sure to use the power supply specified on the nameplate of this slushy machine; if the voltage fluctuation range is large, please install an automatic voltage regulator suitable for power according to the nameplate parameters.

It is necessary to use a separate dedicated socket and reliably grounded, and the power cord of this series of slushy machines is equipped with a three-wire (grounded) plug which should be used. Conforms to standard three-wire (grounded) sockets. Never remove the third pin (ground) of the power cord under any circumstances.

Do not use the power cord if it is damaged or the plug is worn, and it must be replaced at the maintenance point designated by the manufacturer. When there is a leakage of flammable gases such as gas, the valve of the gas leakage should be closed immediately, and then the doors and windows should be opened, and the plug of electrical devices such as the slushy machines should not be unplugged or plugged. Please install a leakage-off circuit protector before use to ensure personal safety and safe use of the product.

Usage

- No trial operation shall be carried out without the guidance of a professional, otherwise, it may cause the failure of the machine and a safety accident

- Do not put your finger in the feeder of the pot, otherwise it may cause finger injury or machine failure. Before disassembling and cleaning the discharge valve and agitator, the power supply must be turned off, otherwise it may cause personal injury.

- Do not spray with water to, rinse the slushy machine, and do not place the slushy machine in a wet place that is easy to splash water, so as not to affect the electrical insulation performance of the slushy machine. It may even lead to accidents such as electric shock and fire.

- It is strictly forbidden to disassemble and transform the slushy machine, and it is forbidden to artificially damage the refrigeration pipeline. Repairs of the slushy machines must be carried out by qualified personnel. In the event of an abnormality or failure, please unplug the power supply, and stop using it, and if you need repairs, you must contact the designated maintenance point.

- When the slushy machine is not used for a long time, please unplug the power plug, otherwise the aging of the insulation layer will cause a leakage fire.

Usage Environment

The slushy machine needs to be placed on solid ground and with the packaging base, and if it is necessary to raise it, it is also necessary to choose a smooth, hard, non-burning countertop, otherwise it may cause dumping, noise, and excessive vibration.

The slushy machines should not be placed in places that are wet or susceptible to splashing water, otherwise, they will cause fires or electric shock.

NOTICE

This appliance is used for similar purposes: e.g. in the kitchen area of a shop, office o,r other workplaces; for customers of farms and hotels, motels, and residential environments;

Family hotel environment; Restaurants and similar non-retail applications.

Installation

Instructions for The Whole Machine

Installation of Slushy Machine

- Remove all packaging components.

- Check if the machine is damaged during transportation, and then remove the attachments.

- This series of slushy machines should be placed in a clean place with air circulation, not suitable for open air, not suitable for direct sunlight and rain, nor can it be placed near the heat source.

- The ambient temperature around the series of machines should not be less than 3 °C/37.4°F, not higher than 38 °C/100.4°F, and the appropriate spacing should be retained around the four sides to maximize the efficiency of the slushy machine and the heat dissipation of the machine.

- When the slushy machine is installed, please place the slushy machine horizontally, and items cannot be placed on the top.

WARNING

When moving, the box should be kept as straight as possible, and the maximum tilt should not exceed 45°. When moving, please ensure that there are at least two or more people, and avoid upside-down and horizontal placement.

The maximum stack cannot exceed 2 layers.

Installation of the Power Supply

- The power supply connected should be the same as the one indicated on the nameplate of the machine.

- Do not connect other electrical appliances to the same outlet.

- The y-type connection must be replaced by the manufacturer, service agencies, or qualified personnel to connect the power cord.

- The power plug should be plugged directly into a power outlet with a ground wire, not into a temporary terminal block. All wiring must comply with national or regional standards.

- Voltage fluctuations shall not exceed ±10% of the rated voltage, otherwise, a voltage regulator shall be installed.

Pre-boot Inspection

- Is the slushy machine placed horizontally?

- Is there any problem with the power outlet?

- Whether the access to the power supply is consistent with the one marked on the machine nameplate.

Proper Operation When Using

- Do not place items on the top cover of this machine, otherwise it will cause noise.

- The left, right, and rear sides of the machine must have sufficient heat dissipation space, otherwise, it will affect the heat dissipation, and the production capacity of the machine ais affected by the air-cooled circulation channel, and it is forbidden to place items around.

- The slushy machine should be kept away from the heat source, it is strictly forbidden to use it in a high or low-temperature environment, and direct sunlight should be avoided as much as possible so as not to affect the heat dissipation of the machine.

- Sterilization should be carried out daily. Otherwise, bacterial multiplication can be detrimental to health.

- If the slushy machine is placed for a long time, please disassemble and wash it, turn off the power plug, please carefully dry the water of the material tank and the freezing tank; after they are dried and then covered with the material basin cover for safekeeping.

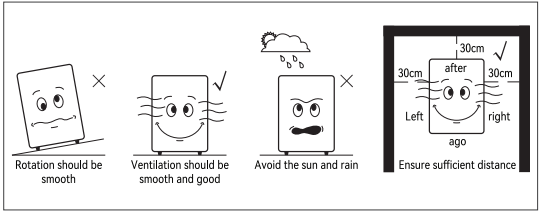

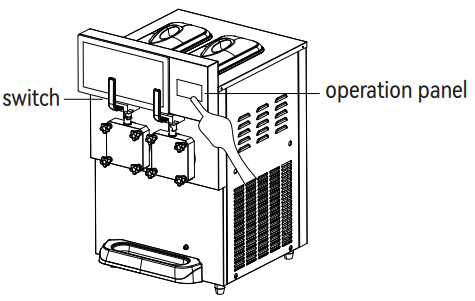

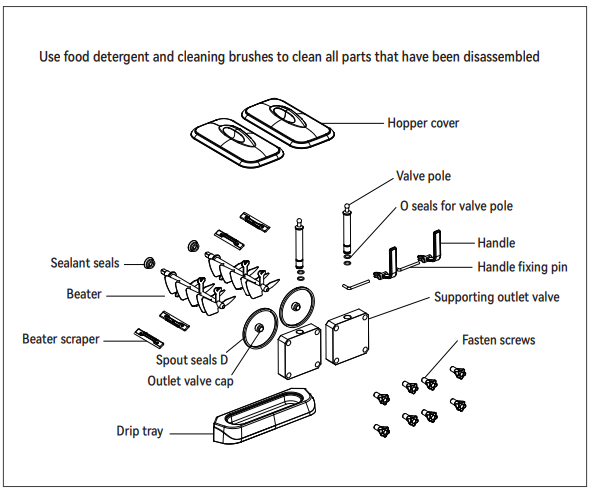

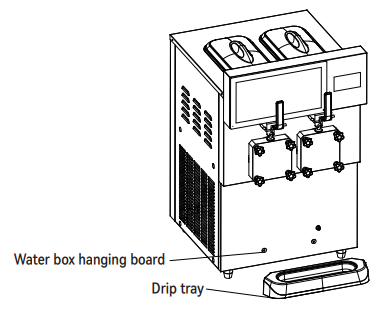

Names of Each Par

Discharge Valve Assembly

Product Specifications

| Model | XRJF-21 |

| Refrigerating Capacity | 24-36L/H |

| Climate Type | N/SN |

| Refrigerating | R410/650g |

| Input Power | 1800W |

| Rated Voltage | AC120V 60Hz |

| Foam Material | Anticyclone |

| Net Weight | 94KG |

| Dimensions | 570*680*925mm |

Operating Instructions

Notice:

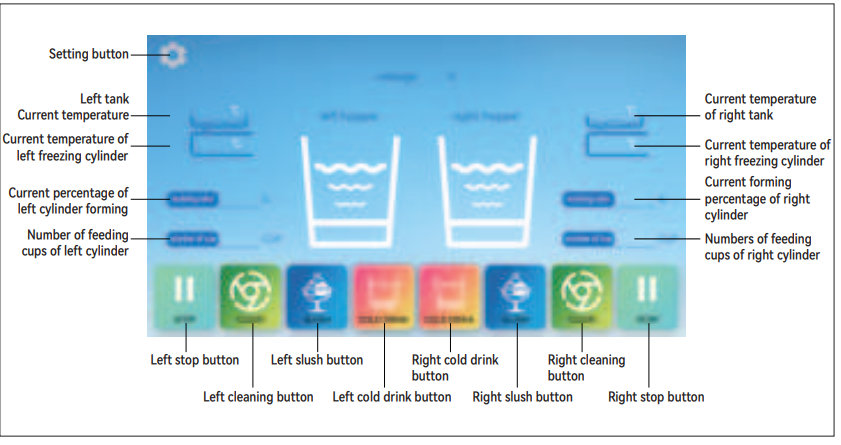

The left cylinder and the right cylinder correspond to the left system and the right system respectively, and the two systems are independently controlled, and the independent displays do not affect each other.

Press “Stop”, “Clean”, “Slush” and “Cold Drink” on the touch screen to enter the corresponding working mode.

It is normal for the current temperature of the freezing cylinder to deviate from the actual temperature of the raw material in the cylinder. Freezing cylinder temperature is not involved in forming control when making slush.

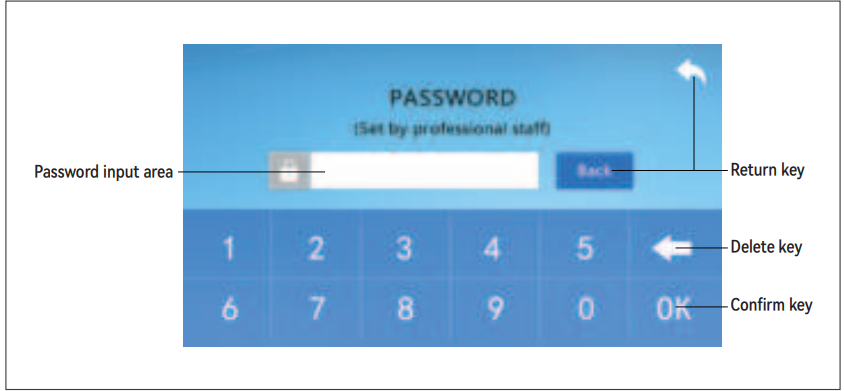

Password Input Interface

On the password input interface, click the password input area enter the password “666666” and then click “OK” to enter the parameter setting interface.

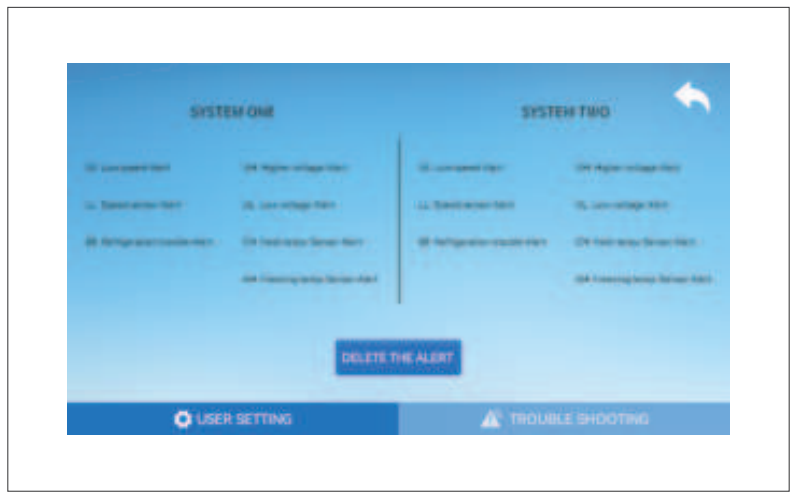

Fault Alarm Interface

On the setting interface, press “Fault Query” on the touch screen to enter the fault query mode. Displays an alarm interface when a fault occurs during machine operation.

- 55 LLow-speed alarm: 220V machine motor speed is lower than 130 rpm to stop the alarm to prevent the motor from being damaged by excessive force. (The motor speed of the 120V machine is lower than 165 rpm and it will stop and alarm.)

- LL sensor is abnormal: When the motor is working but has no speed, it will stop the alarm or prevent the motor from being stuck and damaged or the speed sensor is abnormal. 88 Refrigeration poor alarm: if the longest forming time is exceeded, the poor refrigeration alarm will be reported.

- UH high voltage: when the operating voltage of the machine is higher than the set value, it will stop and alarm, 2 the 20V machine will alarm if it is higher than 255V, and 1 the 20V machine will alarm if it is higher than 135V.

- UL low voltage: when the operating voltage of the machine is lower than the set value, the machine will stop and alarm, the 220V machine will alarm if it is lower than 182V, and the 120V machine will alarm if it is lower than 96V.

- AH return air temperature is abnormal: when the material cylinder temperature probe is damaged or abnormal, it will stop and alarm.

- Clear fault: clear all faults and re-test.

System 1 (left cylinder) parameter setting interface

- Slush gear: 1-8 gears are adjustable, press “plus” or “minus” to adjust the gear, The default is gear 3. The higher the gear, the harder the smoothie; and the lower the gear, the smoother you make is softer.

- Slush cycle time: This time adjusts the cooling system after the slush is 100% formed Stop time, adjustable from 5-20 minutes, press “plus” or “minus” to adjust the gear The default is 10 minutes.

- Preservation temperature: Set the preservation temperature of the tray, adjustable from 5° C to 15° C, and the default is 10°C.

- Cold drink temperature: Set the cold drink refrigeration shutdown temperature, adjustable from 2 °C to 10°C, and the default is 7°C.

- Number of cups delivered: Record the number of cups delivered by the machine for slush and cold drinks, and press “Clear” to subtract to clear the data.

- Restore factory settings: All data set by the user is cleared, and the parameters are restored to the factory settings.

- Next page: Enter system 2 (right cylinder system) user settings.

Note: All user-set parameters have a power-off save function, which will be automatically saved after the setting is completed and returned.

System 2 (right cylinder) parameter setting interface

The parameter setting method of system 2 (right cylinder) is the same as that of the left cylinder.

Out-of-Material Alarm Function

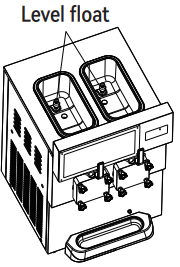

The bottom of the tank is equipped with a level float, any one of the levels floats at a low level, RRA reports lack of mated raw and raw materials to the tank level float to float, and the lack of material alarm is closed.

The bottom of the tank is equipped with a level float, any one of the levels floats at a low level, RRA reports lack of mated raw and raw materials to the tank level float to float, and the lack of material alarm is closed.

Slush Production

- Raw Material Preparation

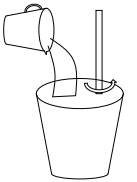

According to the manufacturer’s operating instructions, dilute the concentrate with water and stir in a suitable container. The mixture contains sugars, the amount of which should be kept between 13%-18%. Lower and higher concentrations can be destroyed by agitators and stirring motors.

According to the manufacturer’s operating instructions, dilute the concentrate with water and stir in a suitable container. The mixture contains sugars, the amount of which should be kept between 13%-18%. Lower and higher concentrations can be destroyed by agitators and stirring motors. - Raw Material Filling

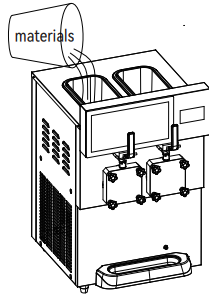

Before adding the raw materials, try to ensure that there is no residual moisture in the freezing tank during cleaning. Check the discharge valve assembly, whether it is installed in place, and whether the four fastening nuts are twisted. Inject about 6 liters of slush raw material into the material tank,

Before adding the raw materials, try to ensure that there is no residual moisture in the freezing tank during cleaning. Check the discharge valve assembly, whether it is installed in place, and whether the four fastening nuts are twisted. Inject about 6 liters of slush raw material into the material tank,

(The single-tank slushy machine can pour up to about 10 liters of raw material into the material tank.)

Each freezing tank of this machine is equipped with an independent stirring system, and the system can act independently on one side. - Start The Machine

Refer to the operating instructions Note: When the machine is in working condition, do not put your fingers into the feed bowl raw material supply port. Failure to do so may result in finger injuries or machine malfunction.

Refer to the operating instructions Note: When the machine is in working condition, do not put your fingers into the feed bowl raw material supply port. Failure to do so may result in finger injuries or machine malfunction. - Make Smoothies

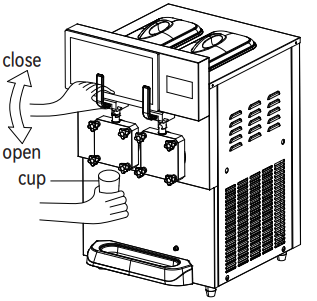

When the shape ratio reaches 99% and the machine is automatically stopped, it means that the smoothie is ready. Simply pull the handle down to punch out the smoothie.

When the shape ratio reaches 99% and the machine is automatically stopped, it means that the smoothie is ready. Simply pull the handle down to punch out the smoothie.

Simple Cleaning

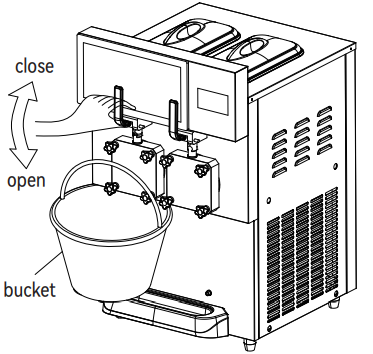

- Release all the ingredients

- Power off the machine

- Fill the material tank with an appropriate amount of food detergent to prepare hot water that does not exceed 50 ° C, then open the tank cover and pour the hot water into the tank.

- Turn on the power of the machine, then press the wash button and let the agitator stir for 2-3 minutes.

- Release all the water from the tank, and then repeat the operation more than 2-4 times.

- Turn off stirring and power.

Note: Please pour clean water into the corresponding basin to be cleaned, do not exceed the highest marking line on the tank, if you want to clean the machine thoroughly, please turn off the machine power.

Cleaning & Maintenance

- Be sure to unplug and turn off the power supply before cleaning.

- Before any cleaning or maintenance, be sure to bring protective equipment (glue hands sleeves, protective glasses, etc.), which ensures your safety.

- Please do not rinse the slush with water spray, so as not to affect the insulation performance of the electrical appliances, and cause leakage hazards.

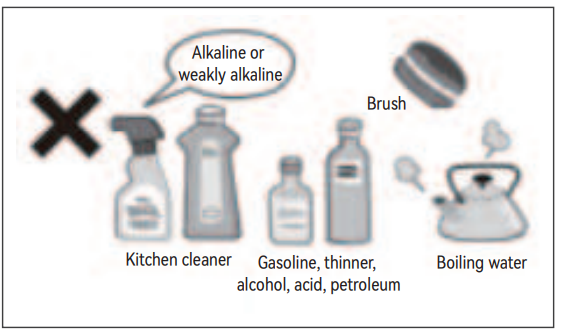

- Do not use hard bristle brushes, wire brushes, detergent powders, gasoline, bananas, water, acetone, other organic solvents, boiling water or acids, alkalis, etc. to clean the slushy machine; improper use will cause damage to the slushy machine material and affect the service life.

- When cleaning a location with warning signs, be careful not to scratch your hands.

- Wash with disinfectant that meets food hygiene requirements.

- Use a suitable food-grade neutral cleaning agent to avoid damaging parts.

The following items can damage the surface of the slush.

Cleaning Method of Parts

User Considerations

Do not damage or lose components during operation. Do not wash resin parts with hot water or a dishwashing machine. Failure to do so may cause deformation. Do not soak parts in detergents or germicidal solutions for more than 30 minutes.

Failure to do so may cause deterioration. For some areas that are prone to accumulation of residual material, please wash carefully with a cleaning brush. Some parts have pointed edges, be careful not to scratch your hands. Carefully wash the agitator with a washing brush, including the middle par

The Assembly Method of The Component

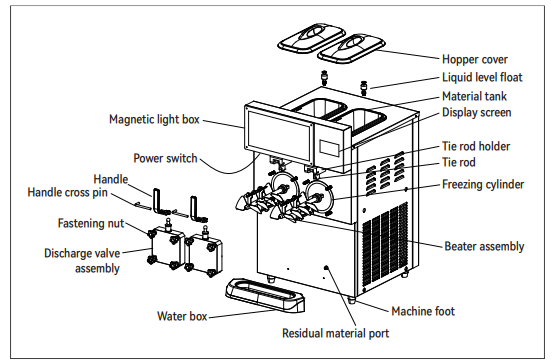

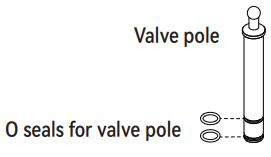

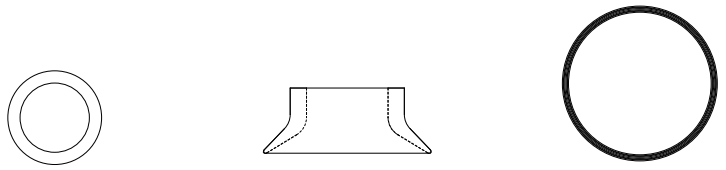

Assembly of The Valve Stem

- Install the O-ring on the valve stem and assemble it according to the diagram.

- After the O-ring is installed, the surface is greased

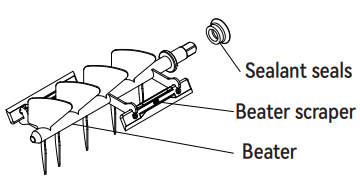

Assembly of Agitator Components

- The flared sealing ring is lubricated at both ends.

- Install the flared seal directly behind the agitator.

- Mount the scraper on the agitator. The spatula arrangement in the agitator is loose.

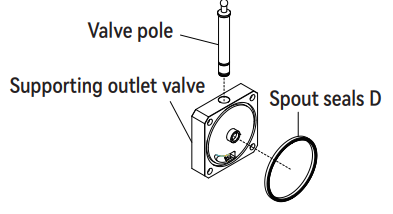

Assembly of Discharge Valves

- Insert the greased stem of the installed O-ring into the outlet hole of the discharge head.

- Install the D-ring on the discharge head mounting slot.

Methods for Installing on The Machine

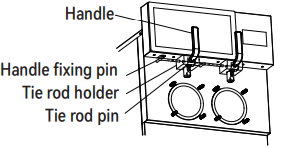

Mounting of The Handle

Insert the handle socket into the lever pin, then insert the handle pin into the lever holder, and then align the handle pinhole with the vel pin, and then the vel pin goes directly through the handle pinhole

Insert the handle socket into the lever pin, then insert the handle pin into the lever holder, and then align the handle pinhole with the vel pin, and then the vel pin goes directly through the handle pinhole

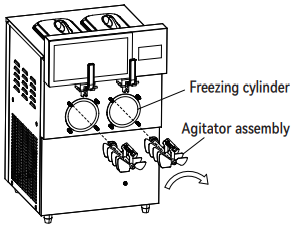

Installation of Agitators

It is important to ensure that the control power switch is turned off. Confirm that the display is off. Insert the agitator into the freezer tank and slowly rotate the agitator with your hands to embed the quad head of the reducer into the quad connector of the reducer.

It is important to ensure that the control power switch is turned off. Confirm that the display is off. Insert the agitator into the freezer tank and slowly rotate the agitator with your hands to embed the quad head of the reducer into the quad connector of the reducer.

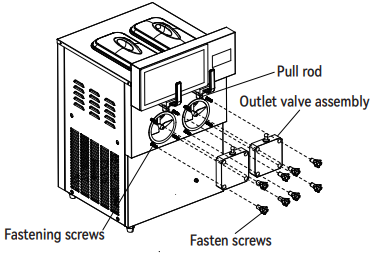

Installation of Discharge Manifolds

The four mounting holes of the discharge valve are passed through the four discharge heads to fix the bolts, the stem head is stuck into the lever clamp position, and then the four fastening nuts are evenly fastened diagonally

Installation of Discharge Manifolds

The four mounting holes of the discharge valve are passed through the four discharge heads to fix the bolts, the stem head is stuck into the lever clamp position, and then the four fastening nuts are evenly fastened diagonally

The four mounting holes of the discharge valve are passed through the four discharge heads to fix the bolts, the stem head is stuck into the lever clamp position, and then the four fastening nuts are evenly fastened diagonally

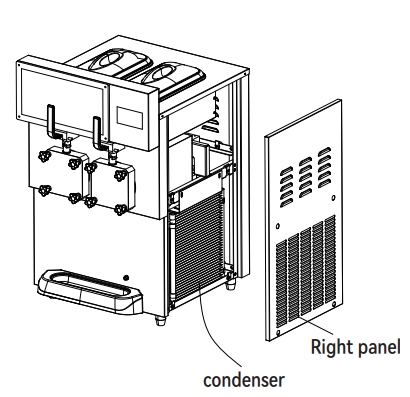

Cleaning of The Condenser

After working for some time, the condenser will be dusty affecting the heat dissipation, and the cooling effect will become worse

After working for some time, the condenser will be dusty affecting the heat dissipation, and the cooling effect will become worse

(Manifested as the output of the slush decreases or the slush is difficult to form), please clean once every three months (if the environment is poor, please clean once a month), be sure to ask a professional cleaner to clean, turn off the power before cleaning, and pay attention not to damage the condenser fins of the vessel.

WARNING

Do not touch the condenser fins directly with your hands as this can cause injury. When disassembling the right panel, pay attention to the display protection.

Consumable Parts

Even if there are scars on the sealing ring that cannot be seen with the naked eye, it may cause problems such as “slush leakage”, so please replace the new product regularly with a rough replacement period of three months. Even within the replacement period, if there is a problem such as scars, please replace it in time.

- O seals for valve pole

- Sealant seals

- Spout seals D

Troubleshooting Instructions

The slushy machine you receive is a mechanization professional equipment that integrates computer program control, mechanical transmission, and an efficient refrigeration system! You must arrange for your personnel to be responsible for the operation and maintenance of this equipment, at the same time, please understand the installation and maintenance requirements of this equipment in detail.

when purchasing the machine, and receive professional training before use!!! (Very important) The violation of the installation, use, and maintenance requirements of the machine caused by equipment failure, is not within the scope of the company’s warranty!

At the same time, for the problems encountered in the process of use, please strictly follow the following precautions:

| Serial number | Cause Analysis | Processing method | |

| No display after powering on | Is the power switch of the equipment energized | Check the power supply, plugs, and sockets | |

| The internal wires of the machine are chewed or loosened by rats | Hire a professional electrician to replace or fix | ||

| The computer board of the equipment fails | Call the company’s phone number to be handled by the company’s professional staff | ||

| 2 | The power switch tripped after power on | Insufficient input power line or switch load | Hire your professional electrician for replacement |

| The internal circuit of the equipment is chewed or broken by rats | Hire a professional electrician to replace or wrap | ||

| Excessive load on equipment due to high gear setting | I, downward—gear adjustment | ||

| The short circuit inside the motor, circuit board, or compressor | Call the company’s phone number to be handled by the company’s professional staff | ||

| 3 | The feeling of leakage after power on | The machine case has inductive electricity | Check whether the power inlet line is reliably grounded, no grounding wire; if it is worn, you need to replace it with a new one |

| – | Leakage of water and material on or under the discharge head after starting the machine | D-seal is not installed properly | Check whether the two D-rings of the outlet valve are installed in the slot |

| Broken 0-ring of beating rod | Take down the beating rod to check whether the seal at both ends is worn, there is wear need to replace the new | ||

| Fastening screws are not tightened | Tighten the four screws evenly diagonally | ||

| Incorrect disassembly or installation method of beating rod, resulting in broken beating rod seal and leakage of material or water | Gently pull out vertically when disassembling, and always apply medical petroleum jelly as a lubricant when installing, apply it around the valve stem seal, and press down vertically. Do not damage the seal with sharp objects when cleaning. | ||

| 5 | The residual material pipe leaked material and water | The discharge head screw is not tightened | Tighten the four screws evenly diagonally |

| Worn seal at the back end of the agitator | Replace rear-end seal |

| 6 | Abnormal noise after power on | The machine is noisy when pressing the cleaning key | The cleaning noise will gradually reduce after adding raw materials | |

| The ground on which the machine is not horizontal, adjust by yourself | is placed | |||

| The machine is noisy when cooling | The noise will be reduced gradually after adding material when there is a lack of material. | |||

| The gear setting is too high, adjust the gear by yourself | ||||

| Fan noise | Self-check whether there are foreign objects around the fan blades and whether the fixing screws of the fan bracket are loose | |||

| Check whether the wind blade rubs the nest shell when rotating | ||||

| Check whether the fixing screws of the condenser are loose | ||||

| Motor noise | Noise generated by too high gear setting | |||

| The noise of the motor itself | ||||

| The fixing screws of the motor are loose | ||||

| Compressor noise | The condenser has not been cleaned for a long time, the condenser is too dirty resulting in an excessive compressor load | |||

| Internal piping deformation causes vibration noise | ||||

| Compressor normal noise | ||||

| 7 | Smoothie discharges are too soft or too little | Too frequent discharge | Wait until the molding ratio reaches 90% or more before mixing the material | |

| Poor heat dissipation | Solve the problem of ventilation on both sides of the machine, leaving at least one meter of space on both sides | |||

| Not enough gears | Adjusting gears | |||

| Machine cooling system failure | Refrigerant leakage or compressor failure | |||

| 8 | No smoothie or too soft after stopping the machine | The beating handle is not in place | When the handle does not hit downward, the beater switch is not closed and the machine does not start | |

| The first cup is softer after stopping the machine | After a long shutdown, it is normal for the first cup to be softer | |||

| Gear setting too high or too low | Proper gear adjustment | |||

| The downtime setting is too long | Appropriate adjustment of downtime | |||

| Discharge micro switch failure | Replacement of discharge micro switch | |||

| 9 | Machine LL Alarm | Sensing anomalies | Check if there are magnets on the motor or adjust the speed sensor position or replace |

|

| Long buzzer sound, the whole machine stops working | Check if the sensor is out of position or the connection wire is disconnected | |||

| 10 | Machine 55 alarm | Tank freezes | Proper downward adjustment of gear |

| The motor does not rotate or the motor idling speed is slow | Call the company’s phone number to be handled by the company’s professional staff | ||

| Sensor failure or loose sensor linkage | Call the company’s phone number to be handled by the company’s professional staff | ||

| Slow motor speed | Check if the motor is damaged | ||

| 11 | Unable to reach 99 | Improper gear selection | Proper downward adjustment of gear |

| Poor cooling | Check whether the condenser is dirty and blocked, whether the exhaust air is smooth, and whether the refrigerant is less | ||

| The ring temperature is too high, ventilation and heat dissipation are not good, or the air inlet and outlet are blocked | Ensure that the equipment is in a ventilated position and remove obstacles from the air inlet and outlet | ||

| Unstable voltage or insufficient power supply capacity | Ask a professional to handle it | ||

| Refrigeration evaporation cylinder frosts badly or has no frost in the return air pipe when empty | Leakage of slush | ||

| 12 | “UH” alarm | High voltage alarm | Adjust the voltage or add a 6KW regulator |

| 13 | “Ur alarm | Low voltage alarm | Adjust the voltage or add a 6KW regulator |

| 14 | “CH” alarm | Freshness and temperature sensor open or short circuit | Replace the sensor |

| 15 | “AH” alarm | Freshness and temperature sensor open or short circuit | Replace the sensor |

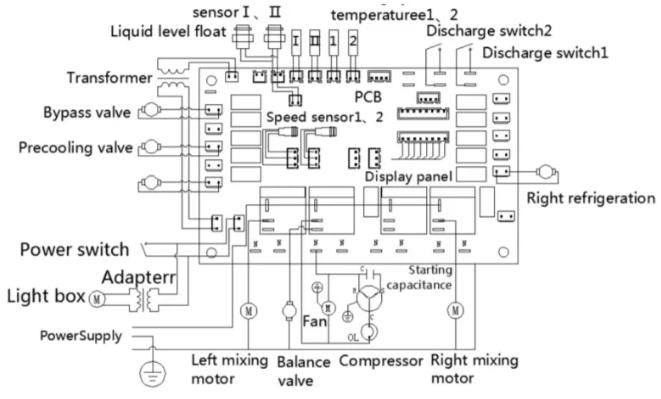

Circuit Diagram

Chute temperature Freezing cylinder

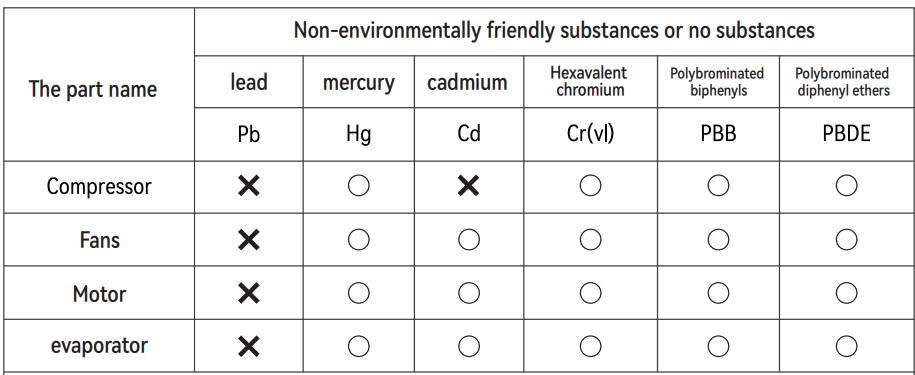

Environmental List

The name and content of non-environmentally friendly substances or elements in the product.

Indicates that the content of the hazardous substance in all homogeneous materials of the part is below the limit requirements specified in GB/T 26572. Indicates that the content of the hazardous substance in at least one of the homogeneous materials of the component exceeds the limit requirements specified in GB/T 26572.

Note: The components of this product are made of non-toxic and harmless green environmental protection materials and the non-environmentally friendly substances or elements contained in this product are due to global technology.

The level of surgery and craftsmanship is limited and it is not possible to achieve complete substitution of non-environmentally friendly substances or elements, but the content of non-environmentally friendly substances or elements in this product Extremely little, long-term use will not cause harm to the human body, please rest assured to use.

Description of the environmental label:

This product is purchased by the relevant provisions of the national regulations “Measures for the Administration of the Restricted Use of Hazardous Substances in Electrical and Electronic Products” Electronic appliances and electrical appliances are used in the industry standard “SJ/T 11364 Requirements for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products” Product hazardous substance control mark.

Instructions for the recycling of waste electrical and electronic products:

ITobetter cares for and protects the earth, when the user no longer needs this product or the product is end-of-life, please comply with the relevant laws and regulations on the recycling of waste electronic and electrical products in the country of use shall be handed over to the local recycling with national approval The processing qualified manufacturer carries out the ecycling.

Any product with a cross-label of the wheeled trash can is a reminder of the obligation to sort and recycle waste. Research on the proper disposal of discarded products will promote environmental protection.

NEED HELP? CONTACT US!

Have product questions? Need technical support? Please feel free to contact us:

CustomerService@vevor.com

This is the original instruction, Please read all manual instructions carefully before operating. VEVOR reserves a clear interpretation of our user manual. The appearance of the product shall be subject to the product you received. Please forgive us that we won’t inform you again if there are any technology or software updates on our product.

Manufacturer: Hubei Guangshen Electric CO.,L td

ADD: Xian’an Economic Development Zone, Xianning City, Hubei Province

Importer: FREE MOOD LTD

Address: 2 Holywell Lane, London, England, EC2A 3ET

EUREP UK LTD

UK REP UNIT 2264, 100 OCK STREET, ABIDING OXFORD SHIRE ENGLAND OX14 5DH

Importer: WAITCHX

Address: 250 bis bBoulevardSaint-German 75007 Paris

E-mail: CustomerService@vevor.com

For More Manuals by VEVOR, Visit Latest Manuals

FAQs About VEVOR XRJF-21 Double Bowl Commercial Slushy Machine

How much time does it take to get a slushy machine ready?

The mixture will expand to three gallons when it begins to freeze in the machine and turn into slush. Making slush without alcohol takes 45 minutes to 1 ½ hours, whereas making it with alcohol takes up to 2 hours.

How often should a slush machine be changed?

every two weeks Every two weeks, or every 500 drinks, slush machines should be thoroughly cleaned and sanitised.

What is the ideal slushie machine temperature?

We’ll explain why slushy machines need lower temperatures—water freezes below zero degrees Celsius. For most machines to create the ideal slushy consistency, the temperature needs to be between -2 and -3 degrees Celsius.

What is the capacity of a slushie maker?

Slushie maker with a single bowl (4–12 litres): Serving roughly 13–40 slushies (10 oz/300 ml), 11–34 slushies (12 oz/350 ml), or 9–27 slushies (16 oz/450 ml) each hour is what you can anticipate.

Can a slushie maker be left running all night?

You can leave your slushie maker on overnight, but no more than 72 hours, if necessary (maybe because you need it ready first thing in the morning).

Are slush machines energy-hungry devices?

What is the electrical consumption of a slushie maker? Slushie makers typically use less than a dollar’s worth of electricity annually. The entire yearly cost of water and electricity for a high-quality frozen beverage dispenser will be between $250 and $300.

How much space does a slush machine have?

There are 10 to 12 gallons of slushie flavour mix in each bowl. Thus, 20 litres can be held at once in a double bowl machine. All you have to do is refill the machine while the celebration continues if you have additional slushie mix.

Can water be used in a slushie maker?

Fortunately, all you need to make the ideal slushie is slushie mix and water.

Is it possible to use coffee in a slushie maker?

ICE COFFEE SIMPLE TO MAKE Add milk to the iced coffee mix. Blend until a smooth consistency is achieved. Pour into the slush/granita maker. It’s ready to be served after around thirty minutes.

Can regular juice be used in a slush machine?

It is advised that you use syrup bearing the SLUSH PUPPiE brand. Any beverage with a high sugar content, such fresh orange juice, can be used in your SLUSH PUPPiE Maker. Please make sure your mixture has a high sugar content if you are not using authentic SLUSH PUPPiE branded syrup as this aids in the reaction that produces the slush.