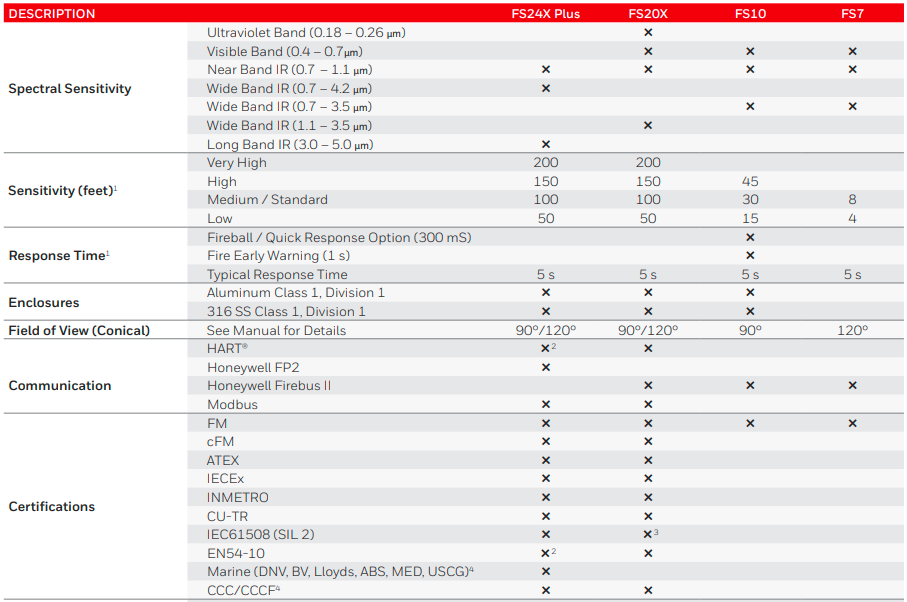

Honeywell FS20X Fixed Flame Detector

QUICK REFERENCE – Honeywell

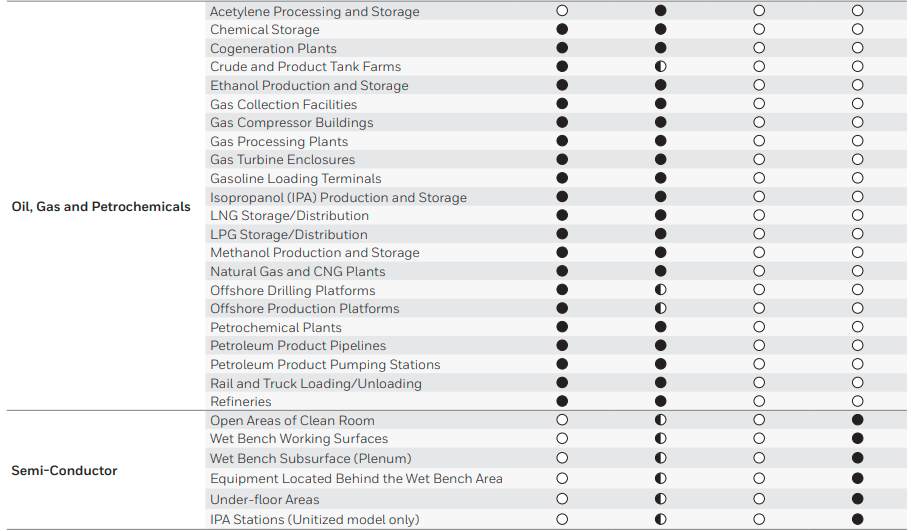

INDUSTRIAL APPLICATIONS

INSTRUCTION

Based on the foundation of the highly successful and reliable SS4 detector, the FS20X is a multi-spectrum (UV/Dual IR/VIS) fire and flame detector with a proven UV solar-blind Sensor. The FS20X exhibits a fast false-alarm-free response to fires over a wider temperature range and with a long detection distance.

FEATURES

- WideBand IR Infrared combined with Ultraviolet

- Detection range greater than 200 feet to 1 square foot heptane fire

- Electronic Frequency Analysis

- Visible sensor for optimum false alarm rejection

- Selectable detection sensitivities

- Solar blind 90° cone-of-vision

- Dual microprocessors for reliable performance

- Real-time clock for accurate time dating of events

- FirePic — up to 6 pre-fire event data storage

- Event log — up to 200 events with date and time stamp

- Built-in RS-485 Modbus Communication

- Built-in non-isolated 4-20 mA analog output (sink or source)

- Alarm, Fault, and Fire Verification relays

- Automatic Optical Path and Electronic Self-Test

- Wide operating temperature range

- Electronics Module for components protection with plug-in terminations for easy field installation

- Two 3/4 inch NPT or 25 mm conduit entries

- FM, ATEX, CE mark approvals

- Meets SIL 2 requirements

BENEFITS

- Detects hydrocarbon and non-hydrocarbon fuel fires in tough environmental conditions

- Minimal maintenance for trouble-free operation

- PC software and Interface Module (FSIM) for fault diagnostics real-time graphs (RTGs) and downloading of FirePics and event log

- Suitable for a wide variety of applications

CERTIFICATIONS

- FM: Class I, Div. 1 & 2, Groups B, C, & D; Class II, Div. 1 & 2, Groups E, F, & G; Class III

- ATEX: II 2 G D; Ex d IIC T4 (Ta: -40 to +110ºC), T5 (Ta: -40 to +75ºC), T6 (Ta: -40 to +60ºC)

- CE: Complies with EN6100-6-4 & EN50130-4, EN54-10:2002 + A1:2005

FS20X SERIES

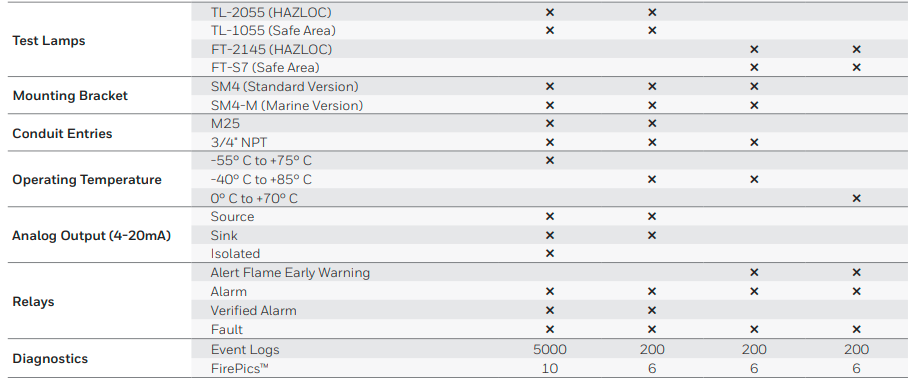

FS20X-211 SERIES, STANDARD TEMPERATURE RANGE -40° TO 85°C

PART NUMBER DESCRIPTION

- FS20X-211-21-2 Dual IR/UV copper-free aluminum enclosure with (2) 3/4″ NPT entries, FM, cFM for Class I, Division 1, Groups A, B, C, D; Class II, Division 1, Groups E, F, G; Class III

- FS20X-211-22-2 Dual IR/UV 316 stainless steel enclosure with (2) 3/4″ NPT entries, FM, cFM for Class I,

- Division 1, Groups A, B, C, D; Class II, Division 1, Groups E, F, G; Class III

- FS20X-211-23-3 Dual IR/UV copper-free aluminum enclosure with (2) M25 entries, FM, FM, ATEX, IECEx for Class I, Zone 1

- FS20X-211-24-3 Dual IR/UV 316 stainless steel enclosure with (2) M25 entries, FM, FM, ATEX, IECEx for Class I, Zone 1

- FS20X-211-21-4 Dual IR/UV copper-free aluminum enclosure with (2) 3/4″ NPT entries, INMETRO

- FS20X-211-22-4 Dual IR/UV 316 stainless steel enclosure with (2) 3/4″ NPT entries, INMETRO

- FS20X-211-23-4 Dual IR/UV copper-free aluminum enclosure with (2) M25 entries, INMETRO

- FS20X-211-24-4 Dual IR/UV 316 stainless steel enclosure with (2) M25 entries, INMETRO

FS20X-212 SERIES W ITH HART®, STANDARD TEMPERATURE RANGE -40° TO 85°C

- FS20X-212-21-2 Dual IR/UV copper-free aluminum enclosure with (2) 3/4″ entries, FM/cFM, HART® module factory installed

- FS20X-212-22-2 Dual IR/UV 316 stainless steel enclosure with (2) 3/4″ entries, FM/cFM, HART® module factory installed

- FS20X-212-23-3 Dual IR/UV copper-free aluminum enclosure with (2) M25 entries, ATEX/IECEx, HART® module factory installed

- FS20X-212-24-3 Dual IR/UV 316 stainless steel enclosure with (2) M25 entries, ATEX/IECEx, HART® module factory installed

- FS20X-212-21-4 Dual IR/UV copper-free aluminum enclosure with (2) 3/4″ NPT entries, INMETRO, HART® module factory installed

- FS20X-212-22-4 Dual IR/UV 316 stainless steel enclosure with (2) 3/4″ NPT entries, INMETRO, HART® module factory installed

- FS20X-212-23-4 Dual IR/UV copper-free aluminum enclosure with (2) M25 entries, INMETRO, HART® module factory installed

- FS20X-212-24-4 Dual IR/UV 316 stainless steel enclosure with (2) M25 entries, INMETRO, HART® module factory installed

ACCESSORIES

- FVR-01 Field of View Restrictor

- PSU-12 Universal charger for Test Lamps for 110-240 VAC with international plugs

- SH-001 Stainless Steel Sunshade

- SM4 Stainless Steel Swivel Mounting Assembly

- TL-1055 Test lamp for FSX and FSX Plus, non-explosion proof, includes universal charger

- TL-2055 Test lamp for FSX and FSX Plus, explosion proof, includes universal charger

REPLACEMENT DETECTOR MODULE

- FS20X-211-10 FS20X Replacement Detector Module

- FS20X-212-10 FS20X Replacement Detector Module with HART®

SPARE PARTS

- FSX-A006 Replacement bulb for TL-1055 or TL-2055

- FSX-A011 Grill kit

- PW-3123-0005 Battery pack for FT-2145/TL-1055/TL-2055 Test Lamp

For more information

HART is a registered trademark of FieldComm Group, Inc.

HIS-CT-FlamePrdctGuide-EN-LTR-2V0-16may2023 © 2023 Honeywell International Inc.

For More Manuals by Honeywell, Visit Latest Manuals

FAQs About Honeywell FS20X Fixed Flame Detector

What is the Honeywell flame detector’s range?

detection range of a heptane fire from more than 200 feet to 1 square foot. Electronic Frequency Analysis Patented*.

How is a Honeywell flame detector tested?

For this test, a Honeywell Analytics Test Lamp is required. Aim the Test Lamp squarely at the front of the Detector (keeping it as close to the test lamp’s suggested distance on the axis as feasible). Press and hold the Test Lamp’s pushbutton to turn it on.

What is the flame sensor’s purpose?

Infrared sensors are commonly used by flame sensors to identify the distinct radiation released by flames. The sensor detects infrared radiation and produces an electrical signal in the presence of a flame.

What is a flame sensor’s minimum allowable reading?

Depending on the boiler, the reading should range from 0.5 to 10 microamps (A) when the flame ignites. Readings in the range of 2 to 6 are typical.

How does one normally detect a flame?

Connect one of your multimeter’s wires to the flame sensor wire and the other to the device from which the wire was unplugged. Activate the device. A measurement between 5 and 10 micro-amps is what you want, with a usual range of 2 to 6.

Why does my Honeywell home’s flame not appear?

The thermostat’s display will only show the flame sign when the boiler is turned on. The Honeywell Home app was not intended to track when the boiler turns on and off, nor was it intended to display the flame symbol to signify the boiler’s state.

What benefits does a flame detector offer?

The technique minimizes equipment damage, worker injuries, and environmental effects by cutting off the fuel source and extinguishing the fire, frequently with the use of a special type of foam. Additionally, the flame detector notifies plant staff who are first responders, enabling them to get to the incident swiftly.

What kind of signal does a flame detector use?

The intensity and spectral quality of blazing embers, coals, and flames can be detected via flame detectors. Systems for detecting flames come in three varieties: infrared, ultraviolet, and infrared/ultraviolet.

Is it possible for a flame sensor to measure temperature?

A specialized instrument called an infrared sensor for flame temperature uses infrared radiation to determine the temperature of flames. Without coming into close touch with the flames themselves, it is capable of detecting and analyzing the thermal radiation that is generated by them to correctly calculate their temperature.

Where is a flame detector useful?

Flame Sensing Applications in the industrial and commercial domains encompass a vast array of structures, such as oil and gas pipelines, turbine enclosures, offshore platforms, aircraft hangers, automotive manufacturing facilities, munitions plants, nuclear facilities, and many more.

Do flame sensors malfunction?

If your flame sensor detects no flame, it will immediately turn off the heating unit due to dirt or malfunction. Three shutdowns will often cause a safety ignition lockout in most furnaces.

Why do sensors for flames malfunction?

The most frequent reason for a failing flame sensor is an accumulation of dirt or debris on its surface, which might obstruct its ability to detect flames. Frequent upkeep can help avert this problem, such as cleaning the sensor.

A flame sensor has what number of ohms?

A decent Cad Cell with a nice flame should typically result in a resistance value of 300–1000 ohms. To confirm that there is a flame, the oil primary control typically looks for an electrical resistance of less than 1600 ohms.

What are the flame sensor’s limitations?

The drawbacks of using a flame detector Inadequate flexibility Flame sensors may also not function effectively in environments with high humidity, thick fog, or smoke. Their accuracy may be affected by indoor conditions. Carbon fires: Certain flame detectors are designed to identify a particular kind of fire.

What color does a typical flame have?

orange At 1112–1832°F, red flames appear, and between 1832-2192°F, they turn orange. The flames turn yellow between 2192 and 2552°F, then they turn blue-violet as they get hotter. The most prevalent color for flames is orange.