BUNBUNN N VP17-1SS Pourover Coffee Brewer

About BUNN

Bunn-O-Matic Corporation (BUNN®) has led the way in the production of dispensed beverage equipment since 1957. BUNN, a global partner you can rely on for dependable beverage equipment and exceptional post-purchase service wherever customers are served, was founded on five generations of family entrepreneurship.

With the help of the company’s brand promise Coffee Brewer, A Partner You Can Count OnTM, BUNN has built a devoted global network of home and business clients based on its basic principles of honesty, integrity, and mutual respect.

To satisfy evolving consumer demands, BUNN has adopted cutting-edge new technologies and is still dedicated to providing the best beverage possible Coffee Brewer in every cup for every occasion. A selection of home brewers and a comprehensive range of commercial beverage dispensing solutions are offered by the equipment portfolio.

These solutions include multi- and single-cup coffee and iced tea brewers, superautomatic espresso machines, coffee bean grinding systems, dispensers for exceptional-tasting cold or hot beverages (such as juice, lemonade, hot chocolate, cappuccino, and iced coffee Coffee Brewer), liquid coffee dispensers, gourmet ice systems, water quality systems, precise temperature water systems, paper filters, and other related items.

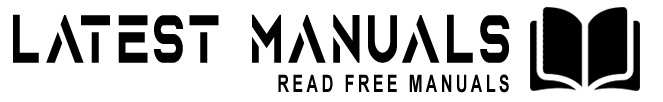

USER NOTICES

Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should be kept in good condition. Replace any unreadable or damaged labels.

CE REQUIREMENTS

- This appliance must be installed in locations where it can be overseen by trained personnel.

- For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C.

- The appliance shall not be tilted more than 10° for safe operation.

- An electrician must provide electrical service as specified in conformance with all local and national codes.

- This appliance must not be cleaned by a water jet.

- This appliance can be used by persons aged 18 years and above if they have been given supervision or

instruction concerning the use of the appliance in a safe way and if they understand the hazards involved. - Keep the appliance and its cord out of reach of children aged less than 18 years.

- Appliances can be used by persons 18 years and above with reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have been given supervision or instruction concerning the use of the

appliance in a safe way and understand the hazards involved. - Children under the age of 18 years should be supervised to ensure they do not play with the appliance.

- If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel

with a special cord available from the manufacturer or its authorized service personnel in order to avoid a hazard. - The machine must not be immersed for cleaning.

- Cleaning and user maintenance shall not be made by children unless they are older than 18 years and supervised.

- This appliance is intended to be used in household and similar applications such as:

- staff kitchen areas in shops, offices, and other working environments;

- by clients in hotels, motels, and other residential-type environments;

- bed and breakfast type environments.

- This appliance is not intended to be used in applications such as:

- farmhouses;

- Access to the service areas is permitted by Authorized Service personnel only.

- The A-weighted sound pressure level is below 70 dBA.

NORTH AMERICAN REQUIREMENTS

- This appliance must be installed in locations where it can be overseen by trained personnel.

- For proper operation, this appliance must be installed where the temperature is between 41°F to 95°F (5°C to 35°C).

- The appliance shall not be tilted more than 10° for safe operation.

- An electrician must provide electrical service as specified in conformance with all local and national codes.

- This appliance must not be cleaned by a pressure washer.

- This appliance can be used by persons aged 18 years and above if they have been given supervision or instruction concerning the use of the appliance in a safe way and if they understand the hazards involved.

- Keep the appliance and its cord out of reach of children aged less than 18 years.

- Appliances can be used by persons 18 years and above with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning the use of the appliance in a safe way and understand the hazards involved.

- Children under the age of 18 years should be supervised to ensure they do not play with the appliance.

- If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with a special cord available from the manufacturer or its authorized service personnel to avoid a hazard.

- The machine must not be immersed for cleaning.

- Cleaning and user maintenance shall not be made by children unless they are older than 18 years and supervised.

- This appliance is intended for commercial use in applications such as:

- staff kitchen areas in shops, offices, and other working environments;

- by clients in hotel and motel lobbies and other similar types of environments;

- Access to the service areas permitted by Authorized Service personnel only

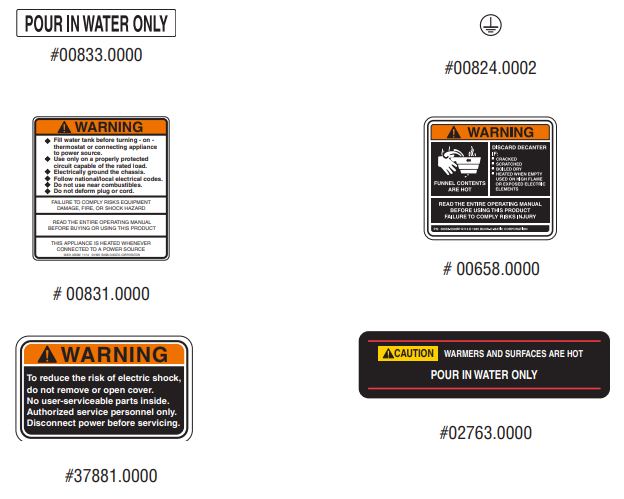

ELECTRICAL REQUIREMENTS

CAUTION – The brewer must be disconnected from the power source until specified in the Initial Set-Up. The 120V brewer has an attached corset and requires a 2-wire grounded service rated 120 volts ac, 15 amp, single phase, 60 Hz.

“A” models require 2-wire, grounded service rated 220 – 240 volts AC, 15

amp, single phase, 50/60 Hz. An all-pole disconnect means must be incorporated in the fixed wiring according to local wiring regulations. Proceed as follows:

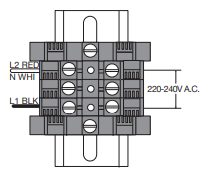

Electrical Hook-Up (Model “B” Only)

CAUTION – Improper electrical installation will damage electronic components.

- An electrician must provide electrical service as specified.

- Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

- Place the heater switch, located on the left front of the control panel on “B” Models, in the “OFF” (lower) position.

- Remove the front panel beneath the spray head.

- Feed the cord through the strain relief and connect it to the terminal block.

- Connect the brewer to the power source and verify the voltage at the terminal block before proceeding. Replace the front panel.

“B” models require 2-wire, grounded service rated 100 volts ac, 20 amp, single phase, 50 Hz. Proceed as follows:

INITIAL SET-UP

CAUTION – The brewer must be disconnected from the power source throughout the initial set-up, except when specified in the instructions

- Insert an empty funnel into the funnel rails.

- Place an empty decanter under the funnel.

- On the “B” Model, place the heater switch of the brewer in the “OFF” (lower) position and connect the brewer to the power source.

- Pour three pitchers of tap water into the screened area on top of the brewer. Allow approximately two minutes between pitchers for water to flow into the tank. While the third pitcher of water is entering the tank, the tank will fill and the excess will flow from the spray head, out of the funnel, and into the dispenser.

- When the flow of water from the funnel stops, place the heater switch of the brewer in the “ON” (upper) position and wait approximately twenty minutes for the water in the tank to heat to the proper temperature. Some water will drip from the funnel during this time; this is due to expansion and should not occur thereafter.

- Pour one pitcher of tap water into the screened area on top of the brewer.

- After water has stopped flowing from the funnel, allow the water in the tank to reheat to the proper temperature.

- Empty the decanter. The brewer is now ready for use by the coffee brewing instructions

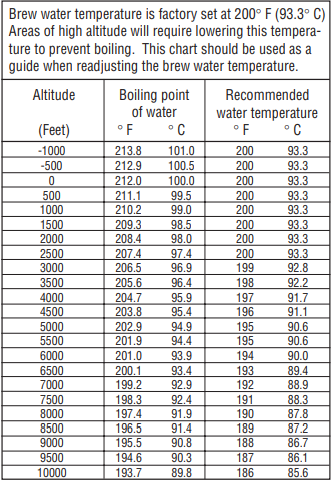

NOTE: The control thermostat will need to be adjusted downward to compensate for high altitudes. Refer to chart.

COFFEE BREWING

- Insert a BUNN® filter into the funnel.

- Pour the fresh coffee into the filter and level the bed of grounds by gently shaking.

- Slide the funnel into the funnel rails.

- Place an empty dispenser beneath the funnel.

- Pour one pitcher of tap water into the screened area on top of the brewer.

- When brewing is completed, simply discard the grounds and filter

LEANING

- The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all surfaces on Bunn-O-Matic equipment.

- Check and clean the spray head. The spray head holes must always remain open.

- With the spray head removed, insert the deliming spring (provided) into the spray head tube. When inserted properly, no more than two inches of spring should be visible. Saw back and forth five or six times.

NOTE – In hard water areas, this may need to be done daily. It will help prevent liming problems in the brewer and takes less than a minute.

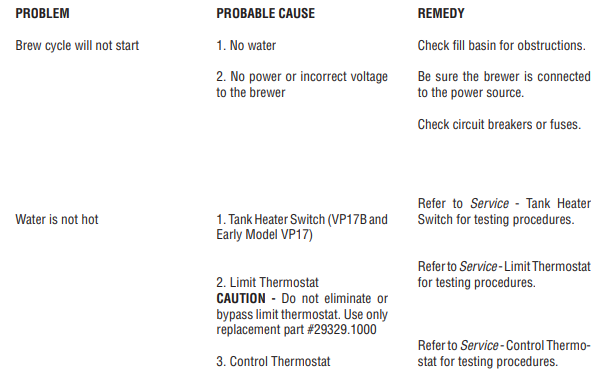

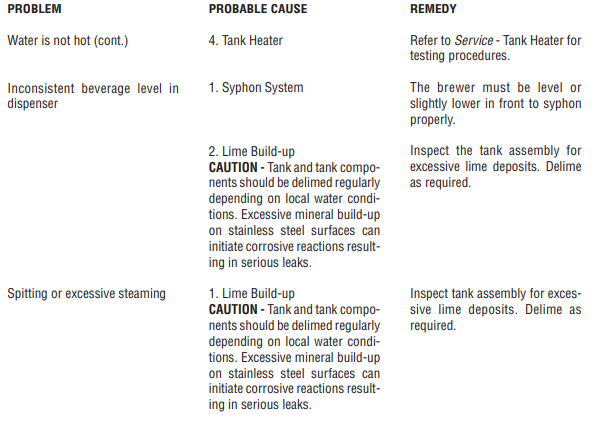

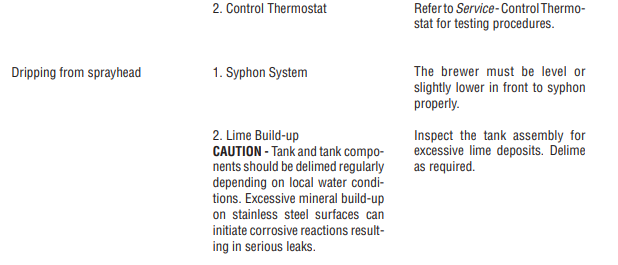

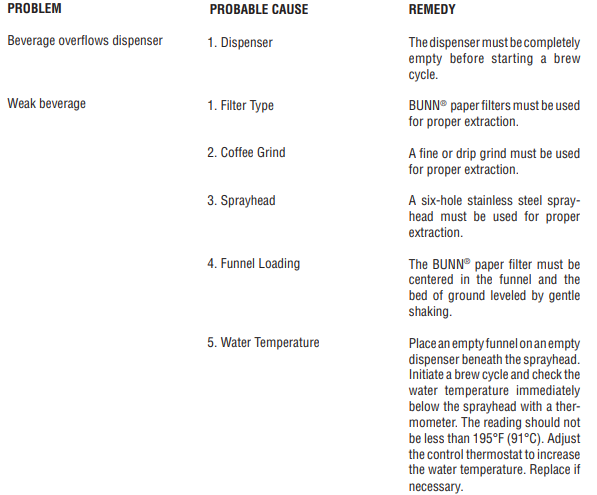

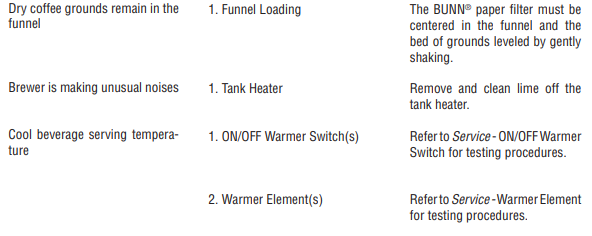

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department.

- Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

- All electronic components have 120-volt AC and low-voltage DC potential on their terminals. Shorting of terminals or the application of external voltages may result in board failure.

- Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a terminal or crimp.

- Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are energized for more than ten minutes without a supply of water.

- The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will help to avoid twists and kinks in the tubing.

- Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

- This brewer is heated at all times. Keep away from combustibles.

WARNING Coffee Brewer

- Exercise extreme caution when servicing electrical equipment.

- Unplug the brewer when servicing, except when electrical tests are specified.

- Follow recommended service procedures

- Replace all protective shields or safety notices

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

- Airports, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCR/MCP/MCA single-cup brewers, thermal servers, and ThermoFresh® servers (mechanical and digital) 1-year parts and 1-year labor.

- All other equipment – 2 years parts and 1-year labor plus added warranties as specified below:

- Electronic circuit and/or control boards – parts and labor for 3 years.

- Compressors on refrigeration equipment – 5 years parts and 1 year labor.

- Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis – parts and labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the applicable warranty period.

This warranty does not apply to any equipment, component, or part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, nonperiodic cleaning and descaling, equipment failures related to poor water quality, damage or casualty.

In addition, the warranty does not apply to the replacement of items subject to normal use including but not limited to user-replaceable parts such as seals and gaskets.

This warranty is conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an authorized BUNN service location, and 3) receiving prior authorization from BUNN that the defective equipment is under warranty.

The agents, dealers, or employees of BUNN are not authorized to make modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the applicable parts and labor warranty periods specified above) to repair the defective components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for the equipment.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of downtime, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized

Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (stylized logo), Velocity Brew, Air Brew, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource, Coffee At Its Best, Cyclonic Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Picture Prompted Cleaning, Pouring Profits, Signature Series, Sure Tamp,

Tea At Its Best, The Horizontal Red Line, and Ultra are either trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

For More Manuals By BUNN, Visit Latest Manuals

- BUNN Heat N Brew Programmable Coffee Maker Owner Manual

- Bonavita BV1901TS 8 Cup Connoisseur Drip Coffee Maker Manual

- Keurig K-Supreme K-Cup Pod Coffee Maker Use and Care Manual

- BLACK DECKER CM1110B Coffee Maker Use and Care Manual

- Ninja CFP101 DualBrew Hot & Iced Coffee Maker Instruction Manual

|

BUNN VP17-1SS Pourover Coffee Brewer Operating Guide [pdf] |